Launch Support

Decreasing product cycles and increasing complexity require a smooth, efficient project launch.

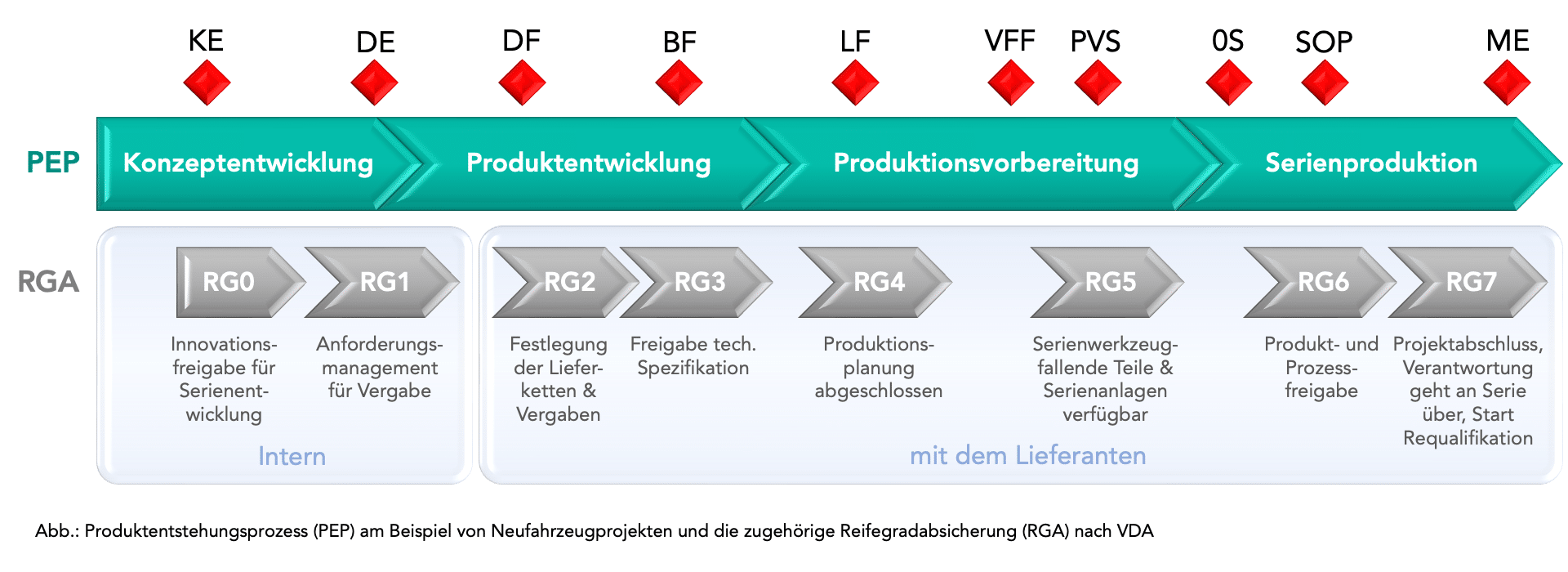

Launch Management & Support from SE to SOP

Product adjustments or suddenly occurring problems can significantly influence and jeopardise project success, especially in the launch phase. As a result, such complications often cause additional costs and maturity level protection is delayed. This throws the entire project schedule out of kilter, jeopardising the calculated market launch volume.

Launch management is therefore responsible for fulfilling the project-specific quality, time and cost objectives. This includes the achievement of the production quantity and peak production, the onboarding of suppliers and the associated securing of parts availability and the validation of product quality.

A particular challenge of launch management is interface management. This includes the networking and coordination of internal and external areas (supplier and OEM, engineering and production).

We use best practice as a recipe for success for processes and project management, because the aspiration of our customers, who are predominantly located in the premium vehicle segment, is the highest possible quality of their vehicles.

Purchase part management

In the automotive industry, the share of purchase parts in OEMs‘ global procurement process has been increasing for years and is driven by more complex products, the implementation of common part and modular strategies, ever-increasing quality requirements from the field (end customers) and increasing statutory regulations.

Ensuring the required product quality in the corresponding quantity at the specified delivery time is indispensable, especially in ramp-up.

Our expertise

- Hot forming parts

- Structural components for BIW

- Aluminium die casting

- Plastic injection moulding & foams

- Structural components for BIW

- Outer skin parts for BIW

- Complex BIW assemblies up to the complete body

- Cold and hot joining techniques

- Interior parts

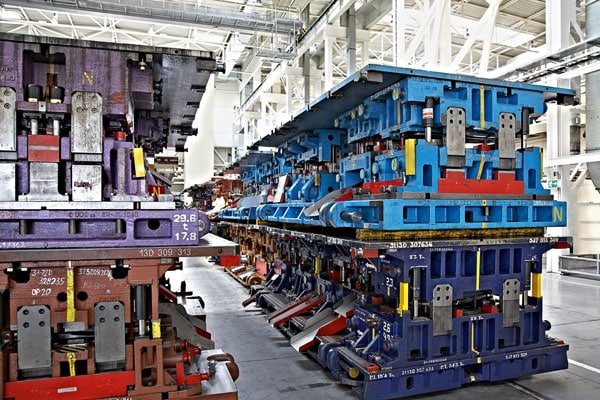

- Stamping tools (transfer- and follow-on composite)

- Aluminium rims

- Steel frames

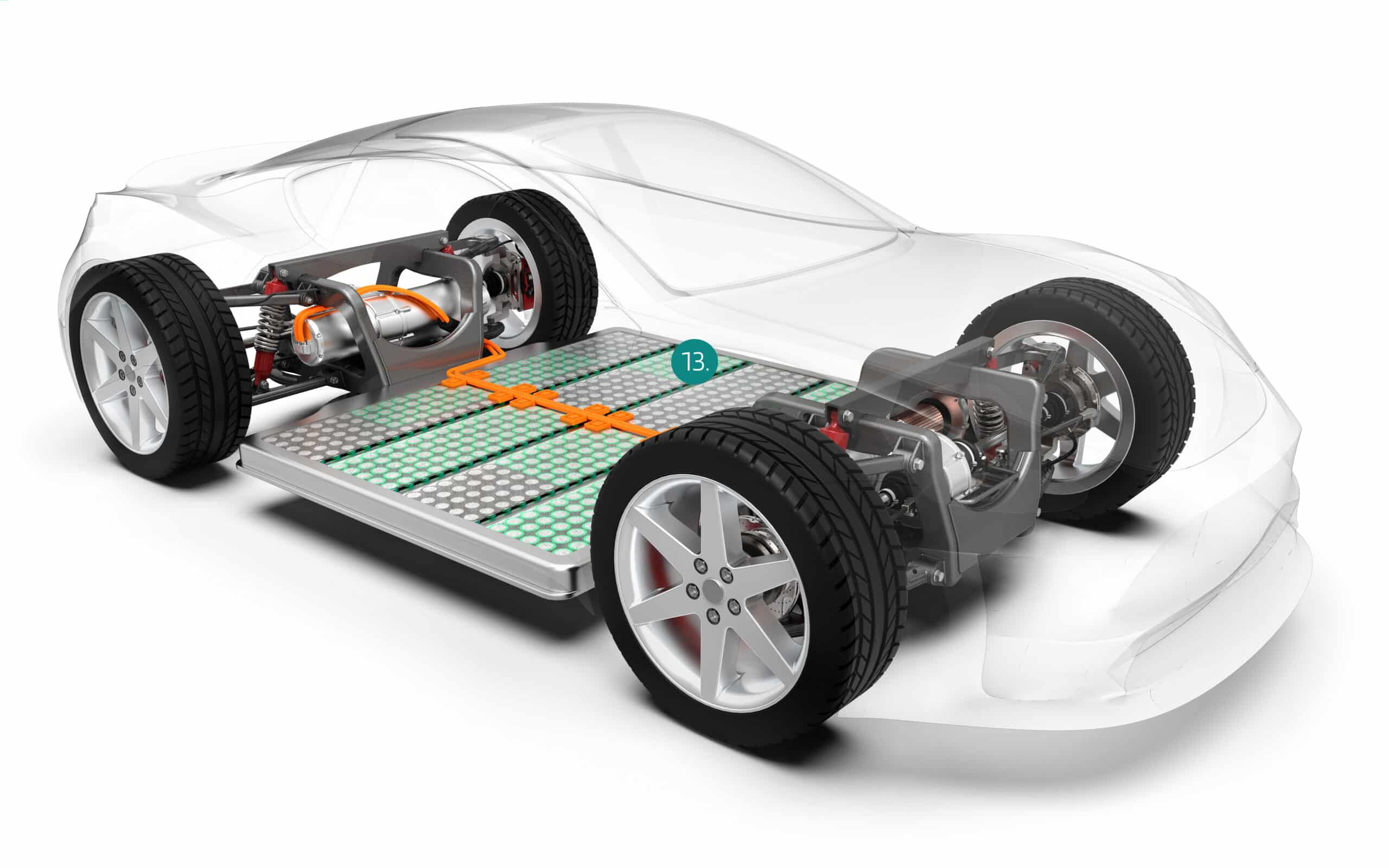

- High-voltage batteries

Supplier Management

40 – 60% of the total costs for the procurement of purchased parts in the automotive industry are incurred from external (Tier 1 n) suppliers. Therefore, the focus in global supplier management is on optimising procurement processes (sourcing). The basis for this is a thorough supplier analysis with subsequent supplier evaluation and continuous supplier tracking and controlling in the project and production process.

This also includes coordination with all stakeholders as well as regular appointments and on-site inspections. In these inspections, the focus is initially on feasibility issues, then on design, tool and system acceptance, and later on stable component quality and delivery reliability.